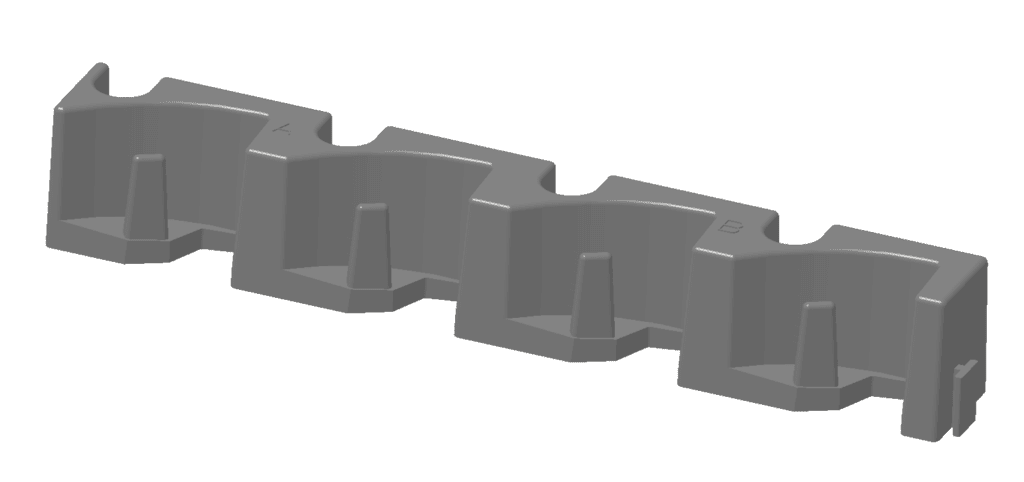

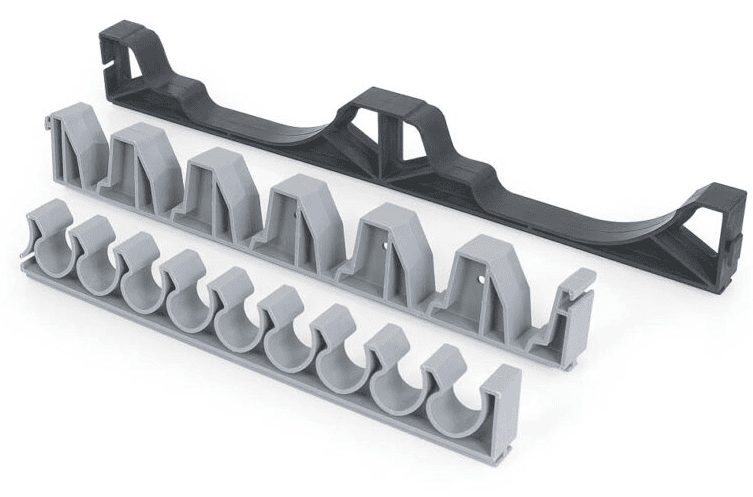

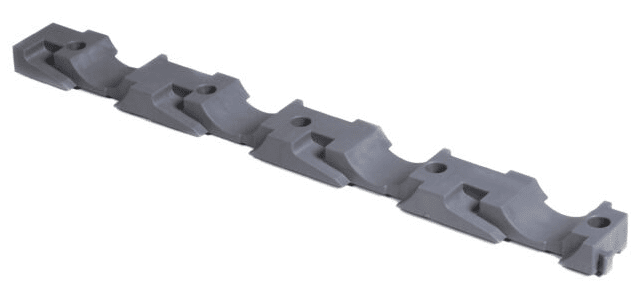

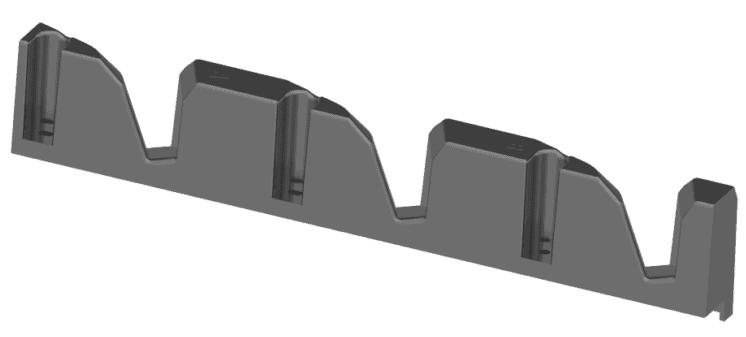

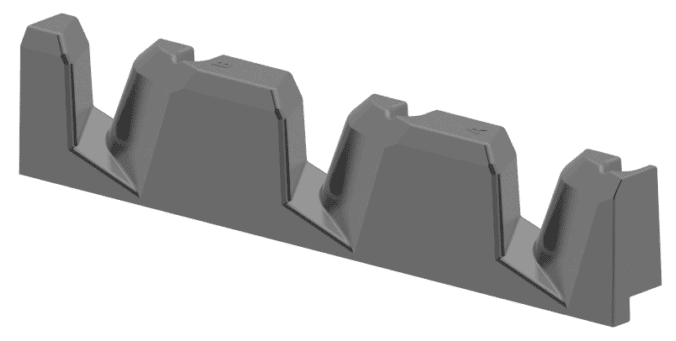

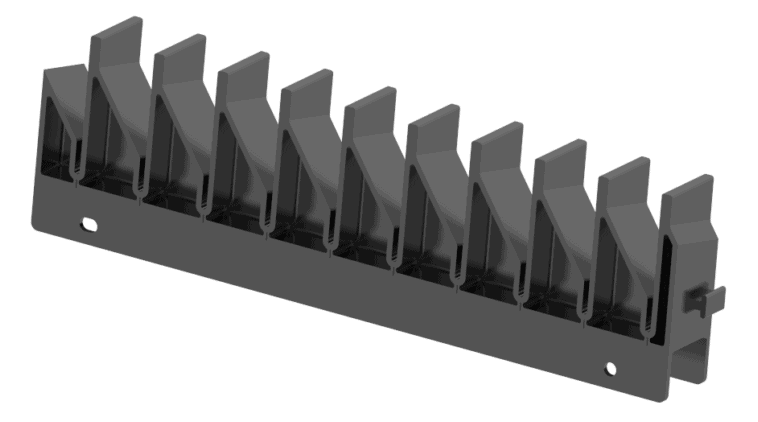

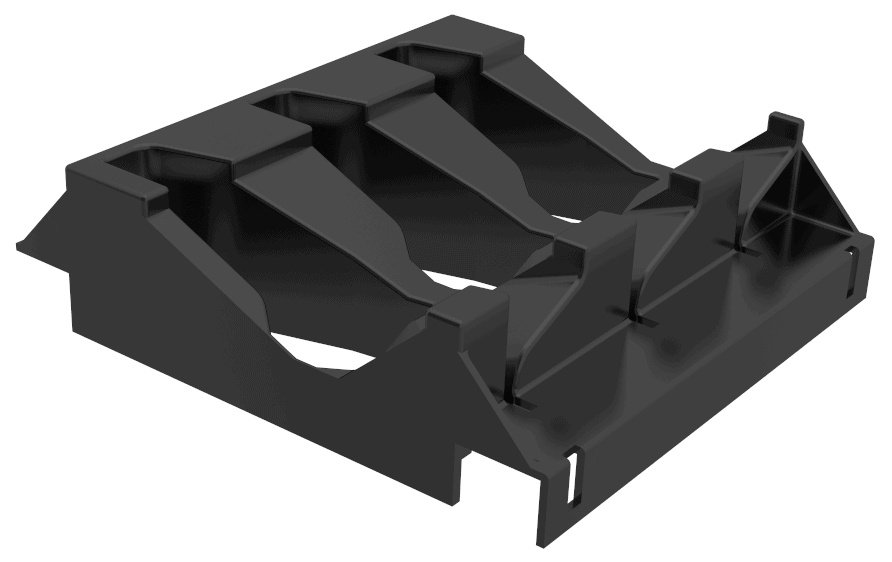

Custom Injection Molded Separator Bars

Custom Injection Molded Separator Bars

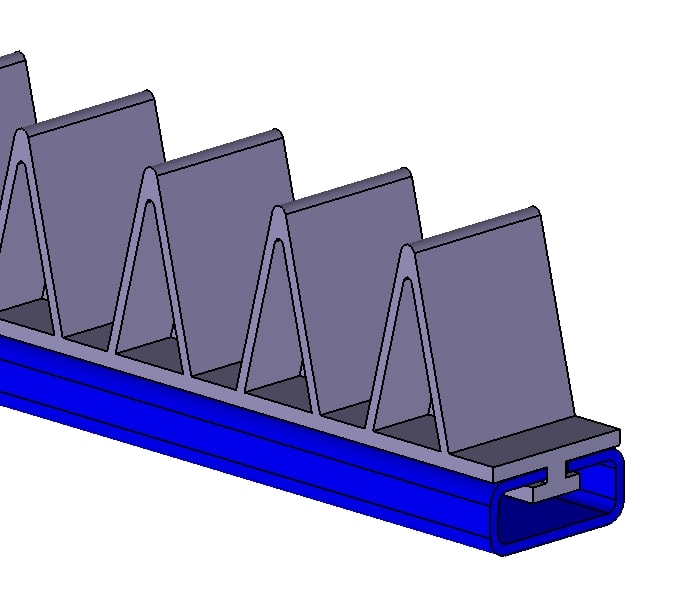

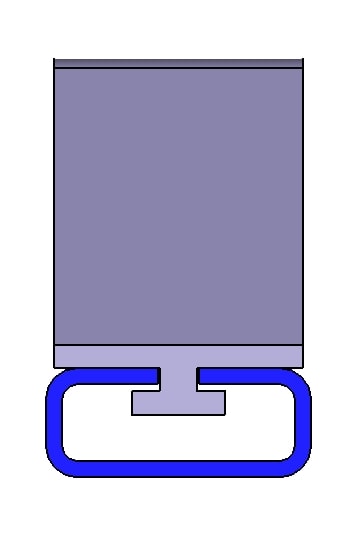

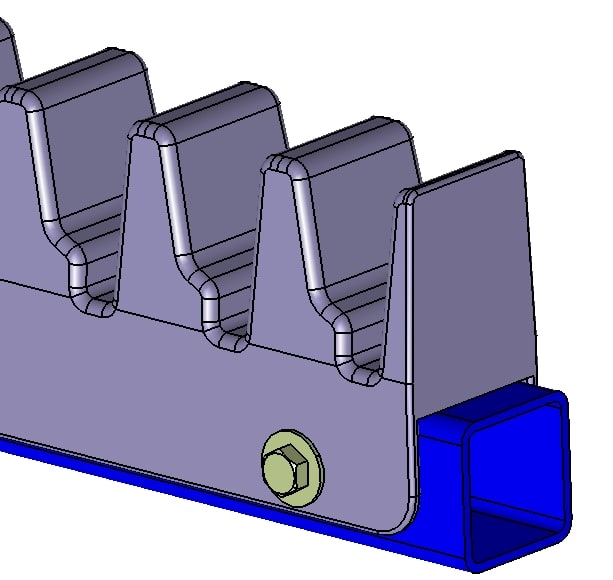

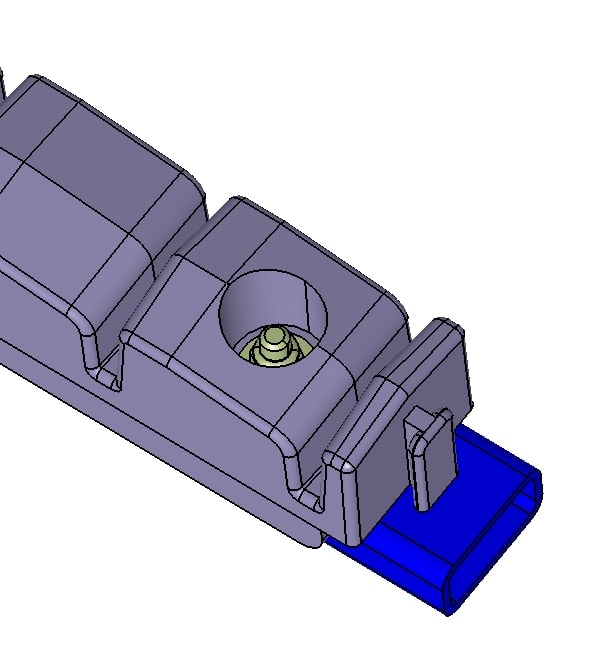

These are bars of dunnage that are usually inserted or attached to steel or aluminum channels or rails and positioned within the container to support and provide separation between the panels or parts being transported or handled. Custom separator dunnage bars can be designed to fit the exact contour of the panel or part, thus providing maximum protection. The pockets are repeated at a certain index spacing to hold multiple units of the same part within a container. Typical applications are sheet metal parts, molded panels, and glass panels. Many material options are available including, but not limited to, thermoplastic elastomer (TPE) for cushioning properties, thermoplastic urethane (TPU) for cut and abrasion resistance properties, and PC/PBT for applications that require strength as well as rigidity.

Get in Touch

See how we can meet your needs for returnable packaging and custom injection molding solutions.

Contact Us Request for Quote