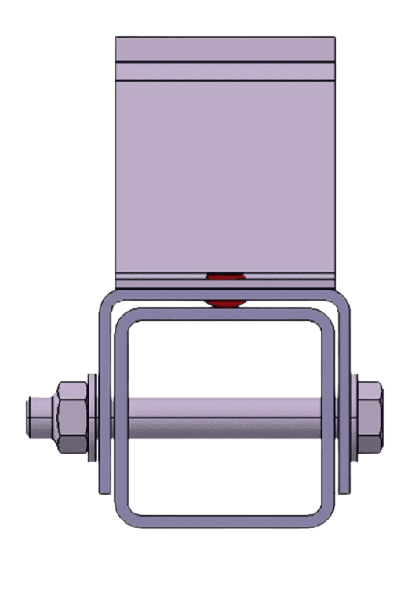

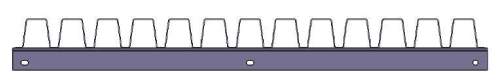

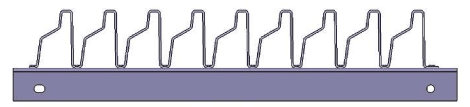

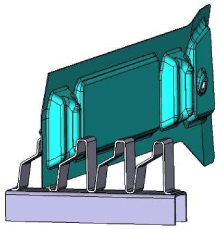

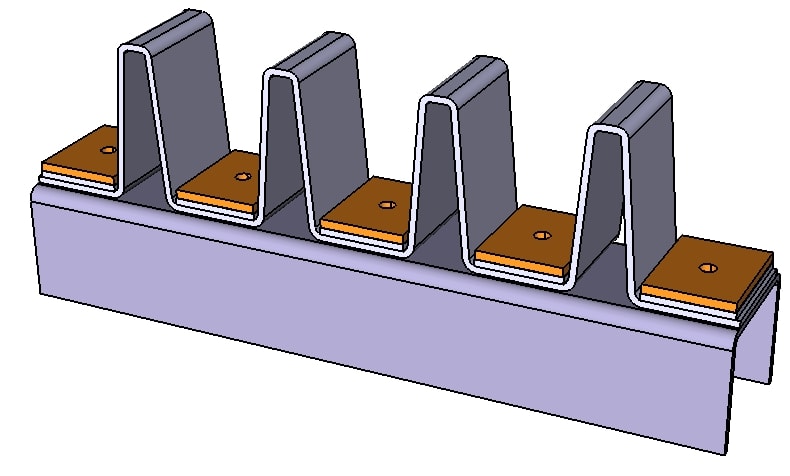

Many shipping rack applications do not require cushioned dunnage designs and in fact benefit from the extremely durable properties which are offered by galvanized steel or stainless steel. In situations where the dunnage does not make contact with the class-A surface of a part, formed steel dunnage bars are a suitable option. In cases where a sharp edge of a sheet metal stamped panel makes contact with the pocket of the dunnage, having the dunnage made from steel is important to prevent damage to the dunnage and to prevent debris contamination from shaving of the dunnage material.

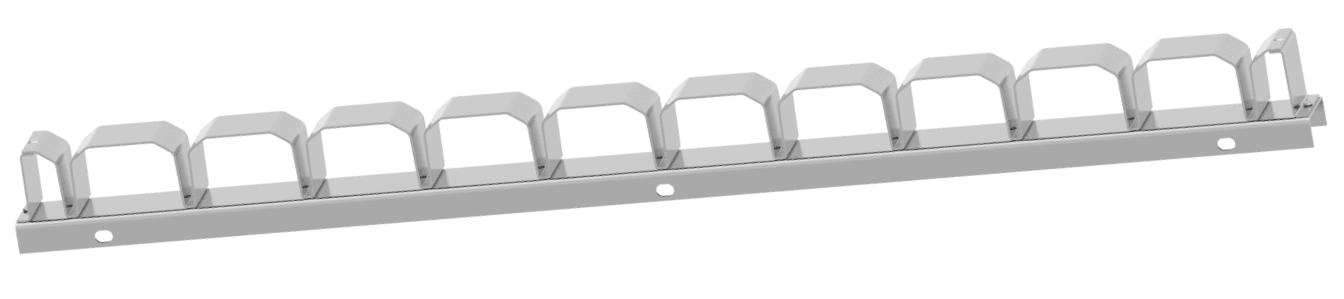

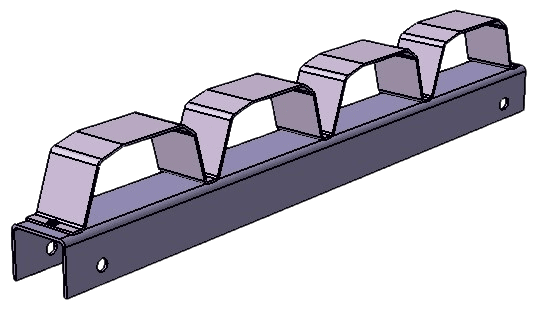

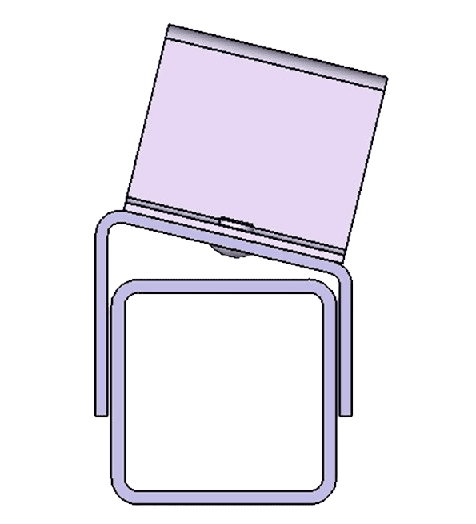

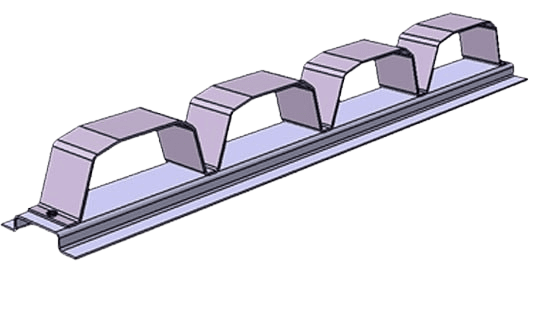

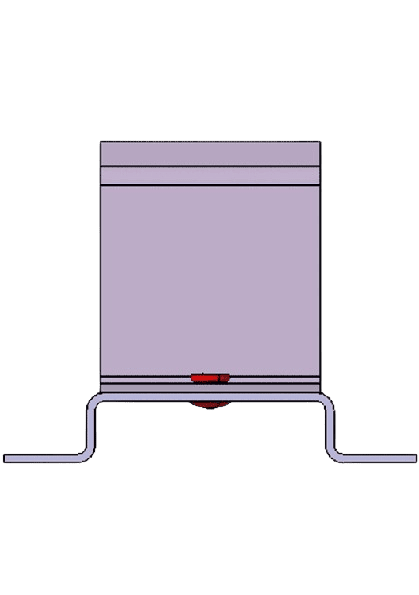

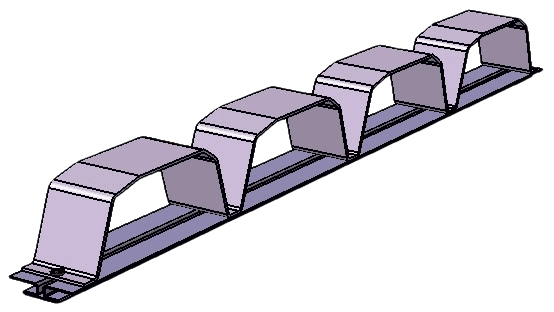

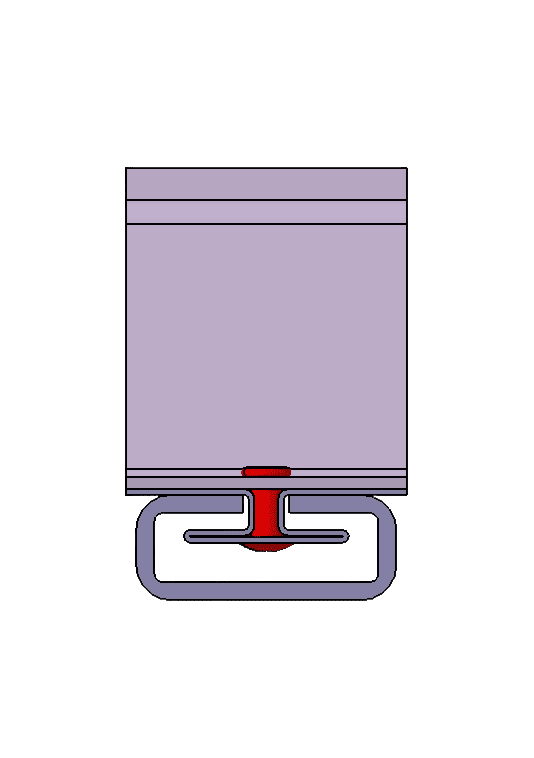

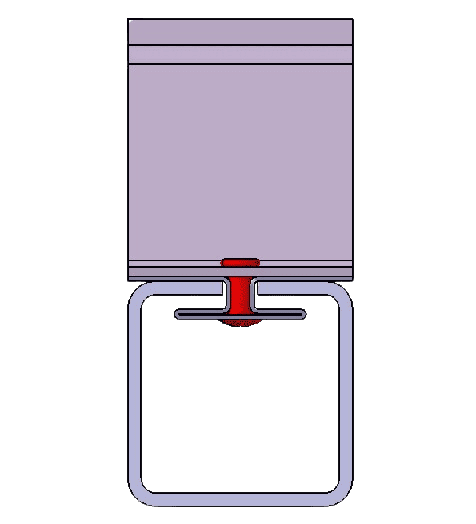

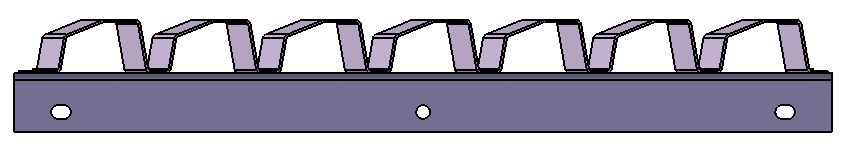

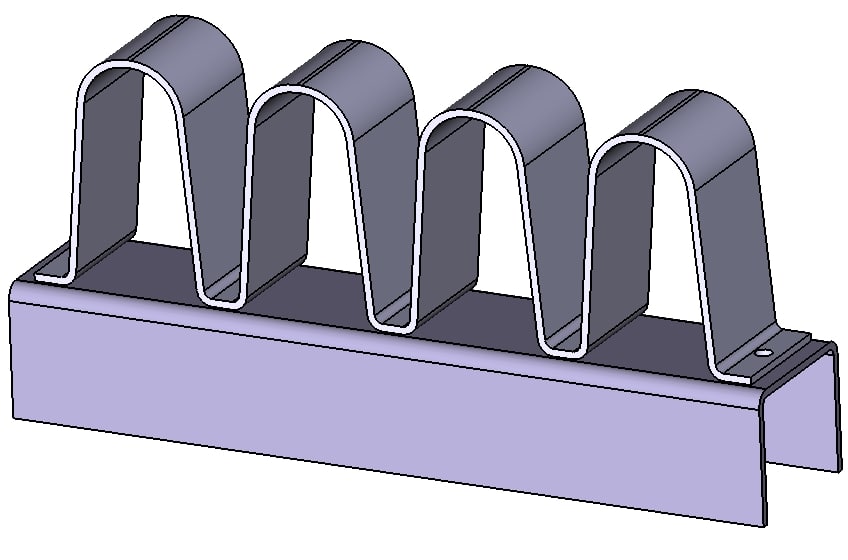

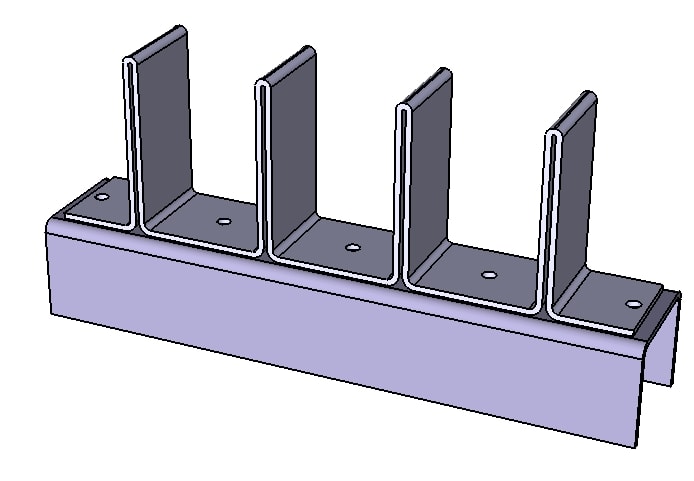

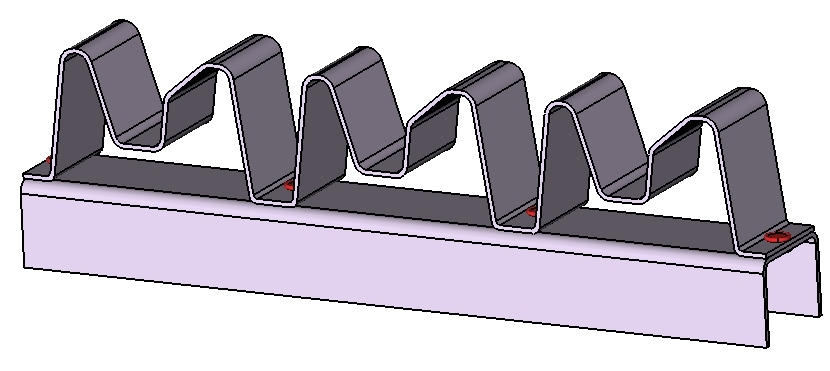

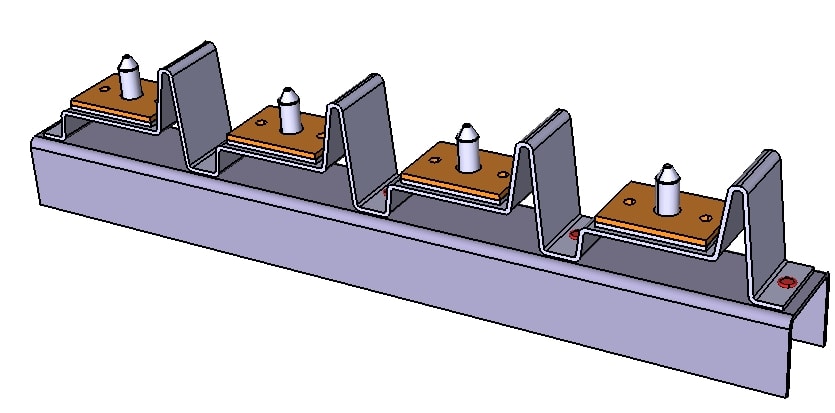

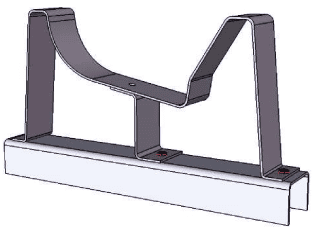

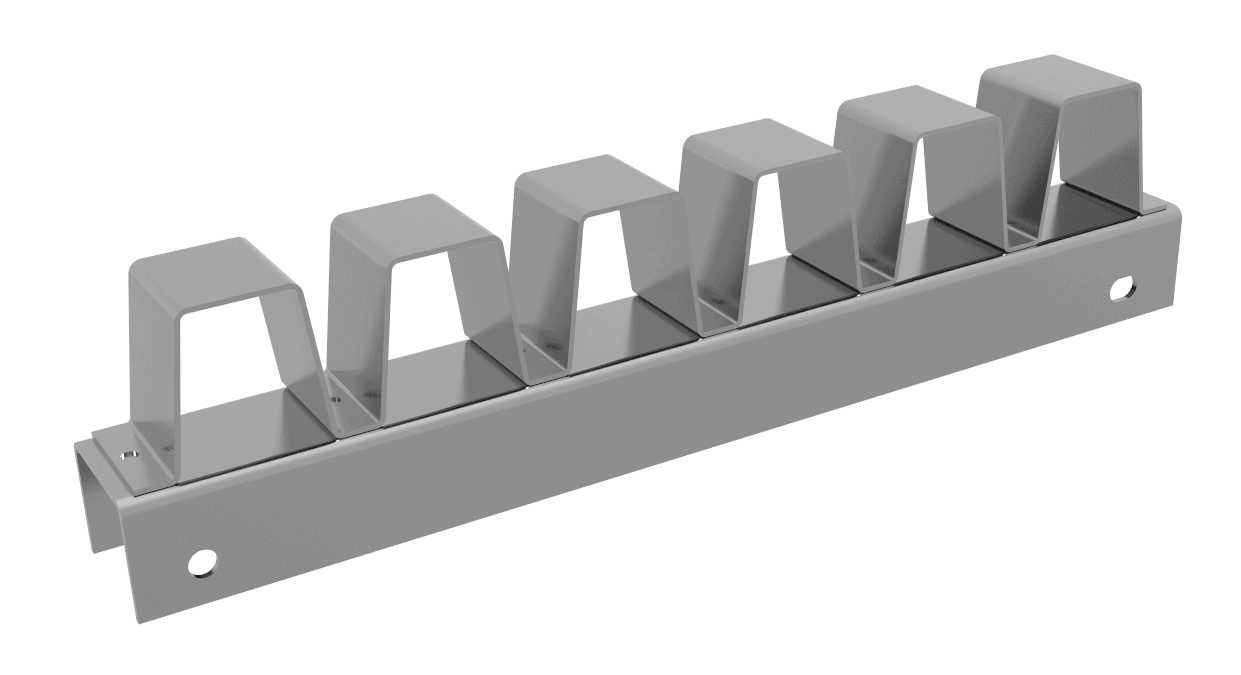

Our process of attaching a continuous formed steel ribbon of pockets onto a steel substrate provides our customers with a bar that can be easily assembled into a shipping rack, cart or other container. Various attachment methods and substrate design options are employed depending on the specific requirements of the project.

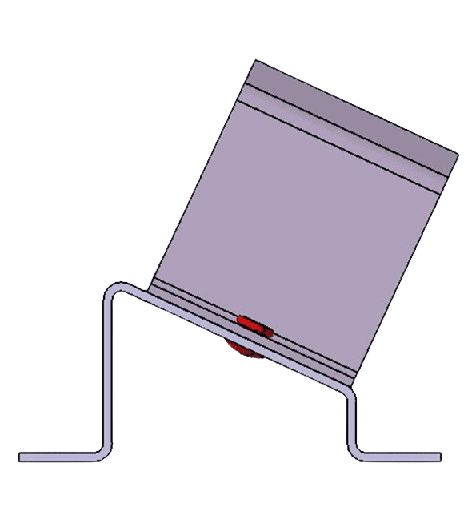

Many pocket shapes can be achieved with our forming methods including deep draw, complex curves, angled designs, and tight spacing. Specialized components can be attached into the assembled bar for more complex solutions. Prototype samples can be developed very quickly and inexpensively. They are identical to actual production parts and therefore can be fully tested before manufacturing.